Fabricated Base Assemblies

Engineered Base Assemblies

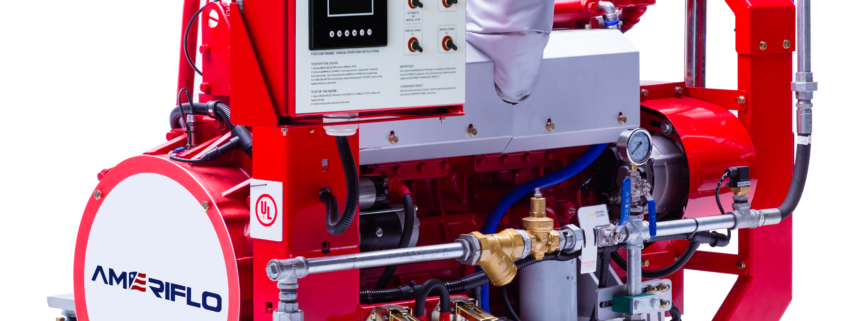

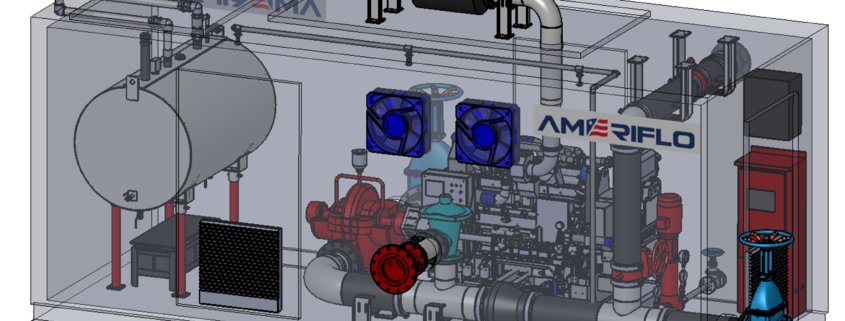

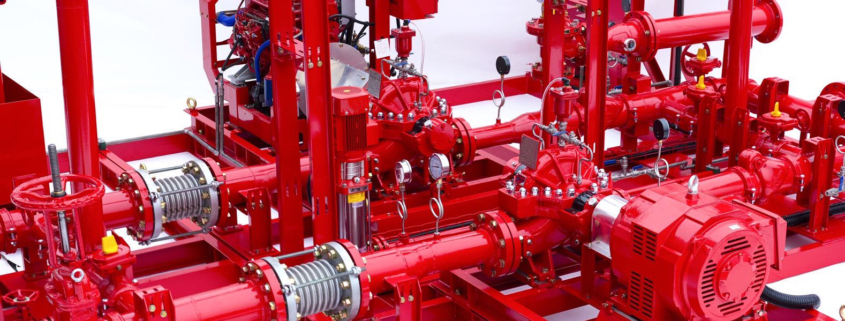

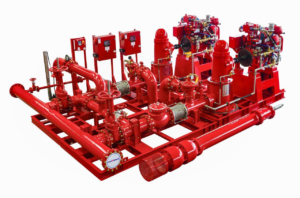

The Ameriflo fabricated base assemblies are some of the best available in the industry. Most of the features and benefits found in these bases are usually found only in bases offered to the API industry. These bases are made of heavy wall structural steel with very high torsional rigidity designed to minimize deflection and keep items mounted in place.

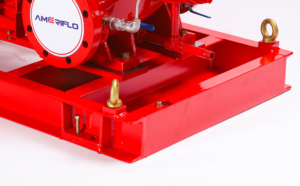

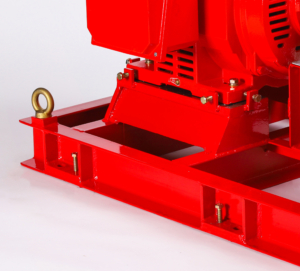

All engineered bases feature milled and drilled pads under both the pump and the driver. These mounting areas ensure that soft foot problems during installation simply are not an issue. Two (2) grounding lugs are present on both short sides of the base making it very easy to ground the entire base assembly increasing safety. Base lifting lugs are installed at each corner of the base allowing for safe lifting and movement of the entire base assembly. These corner lifting lugs stop severe damage that can occur when the lugs on the pump and driver are used to lift the weight of the entire base assembly that are much higher than these were ever intended on supporting. Base leveling jackscrews are installed along the long side of the base making leveling of the entire base assembly very easy and trouble free. These base leveling jackscrews allow for fine tuning of the leveling process that simply cannot be accomplished by using traditional shims.

To aid in the alignment of the pump assembly alignment jackscrews are provided on the driver (when driven by an electric motor) or under the pump (when driven by a Diesel engine). This very simple addition to the base makes field alignment very easy & straightforward and allows for fine tuning of the alignment process that is very useful when performing very precise alignments especially when using laser alignment products.

To aid in the alignment of the pump assembly alignment jackscrews are provided on the driver (when driven by an electric motor) or under the pump (when driven by a Diesel engine). This very simple addition to the base makes field alignment very easy & straightforward and allows for fine tuning of the alignment process that is very useful when performing very precise alignments especially when using laser alignment products.

All base assemblies have capped ends greatly increasing torsional rigidity. Nearly every other manufacturer standardizes on bent channel bases without capped ends. These bases are prone to severe deflection during transport making filed installation more time consuming and very difficult. The Ameriflo I-beam base construction is far superior to these other bent channel designs.

Ameriflo Diesel engines have features that the other Diesel engine manufactures simply do not have. The Diesel engine cradle is a unique and specifiable feature by virtually eliminating Diesel engine vibration that was historically transferred to the pump and system piping. The Diesel engine cradle also houses the emergency contractors, complete cooling loop and the Diesel engine pre-heater. The Ameriflo Vibration Isolation Cradle (VIC) has integral engine mounts that completely isolate the Diesel engine vibration from being transferred to the pump base assembly, This is a feature that no other Diesel engine manufacturer has. This VIC greatly reduces oscillations found from other Diesel engine manufacturers and allows all Ameriflo pump assemblies to operate vibration free.

Ameriflo Diesel engines have features that the other Diesel engine manufactures simply do not have. The Diesel engine cradle is a unique and specifiable feature by virtually eliminating Diesel engine vibration that was historically transferred to the pump and system piping. The Diesel engine cradle also houses the emergency contractors, complete cooling loop and the Diesel engine pre-heater. The Ameriflo Vibration Isolation Cradle (VIC) has integral engine mounts that completely isolate the Diesel engine vibration from being transferred to the pump base assembly, This is a feature that no other Diesel engine manufacturer has. This VIC greatly reduces oscillations found from other Diesel engine manufacturers and allows all Ameriflo pump assemblies to operate vibration free.

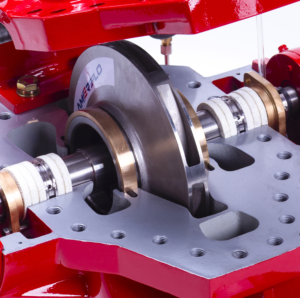

The VI product was built from the ground up with the fire protection market in mind. Every aspect of its design from the actual hydraulic coverage to the materials of construction were built based on the very stringent NFPA 20 standard. This standard describes slope of curve requirements, suction characteristics, hydrostatic pressure requirements as well as bearing and shaft strength requirements. The product line was designed with minimum horsepower as the primary focus and as such, the Ameriflo VI product line has the lowest documented horsepowers available in the fire protection market today!!

The VI product was built from the ground up with the fire protection market in mind. Every aspect of its design from the actual hydraulic coverage to the materials of construction were built based on the very stringent NFPA 20 standard. This standard describes slope of curve requirements, suction characteristics, hydrostatic pressure requirements as well as bearing and shaft strength requirements. The product line was designed with minimum horsepower as the primary focus and as such, the Ameriflo VI product line has the lowest documented horsepowers available in the fire protection market today!!

Ameriflo uses very complex Computational Fluid Dynamics (CFD) software to engineer the maximum efficiency and hydraulic performance from every impeller that they manufacture. Solid Works software allows for the most efficient designing process currently available today. End suction (ES), vertical inline (VI), split case (SC) and vertical turbine (VT) product lines use these impellers as standard construction. The advantages of this engineering design and casting process are visible when you look at the performance curves offered by Ameriflo. Ameriflo leverages technology not available in the past to design and develop the most advanced product lines available in the market today.

Ameriflo uses very complex Computational Fluid Dynamics (CFD) software to engineer the maximum efficiency and hydraulic performance from every impeller that they manufacture. Solid Works software allows for the most efficient designing process currently available today. End suction (ES), vertical inline (VI), split case (SC) and vertical turbine (VT) product lines use these impellers as standard construction. The advantages of this engineering design and casting process are visible when you look at the performance curves offered by Ameriflo. Ameriflo leverages technology not available in the past to design and develop the most advanced product lines available in the market today.