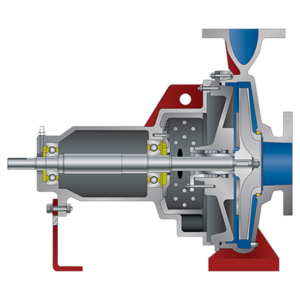

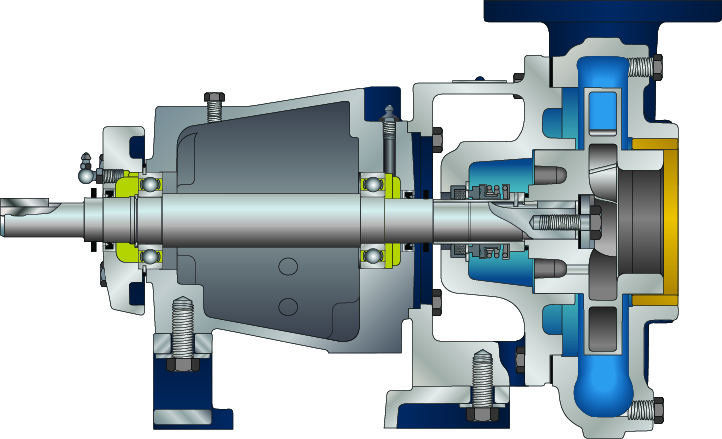

Cast iron, tangential discharge casing with investment cast 304SS impeller & 125# suction and discharge flanges and removable & replaceable case wear ring

Cast iron rear cover with internal flush for component mechanical seal with 304 SS sleeve

Class 30 cast iron power frame with 420SS shafting & 6200 series deep groove bearings

Electric motor or Diesel engine driver available

Back pull out modular power frame design

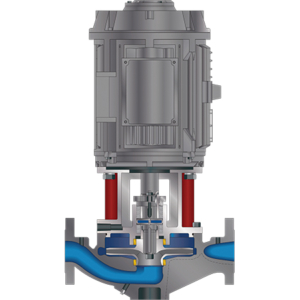

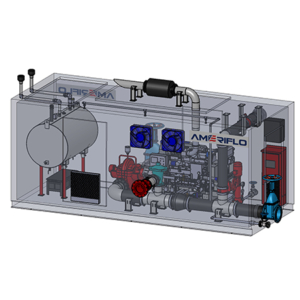

Suction and discharge locations provided with 304 stainless buffer tubing and 304 stainless steel ball valves

Investment cast, 304 stainless steel impellers

Carbon/Silicone-Carbide component mechanical seal with 300 stainless steel hardware

Power frame features industry unique JM register allowing for fewer parts across the product line

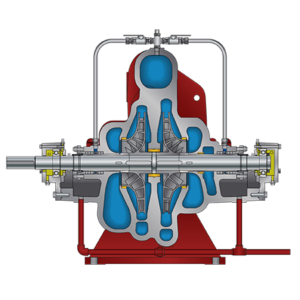

Series 3010 AEF

Flex-Coupled End Suction Pumps

FEATURES & BENEFITS

The Series 3010 AEF End Suction product line is a flex-coupled orientation with a high efficiency, tangential discharge. This product can be electrically or Diesel engine driven and is a perfect fit for the smaller and larger flow applications found throughout the industry.

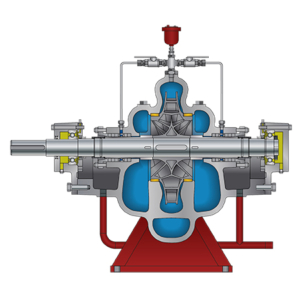

Performance:

Flows: To 4,000 GPM [909 M3/HR]

Heads: To 360 Feet [110 Meters]

Sizes: 1.25×1.5-7 To 8×10-15

Speeds: 3550 RPM, 2950 RPM, 1760 RPM, 1450 RPM, 1180 RPM, 980 RPM

The 3010 Series AEF End Suction product line has the following specifiable features and benefits:

- Cast iron casing and rear cover with 125 PSI pressure ratings

- Full back pull out capability for easy maintenance

- Tangential, high efficiency discharge casing

- 125# suction & 125# discharge flanges

- Investment cast, 304 stainless steel impellers

- 420 stainless steel shafting

- 304 stainless steel shaft sleeve

- Internal flush for mechanical seal

- 6200 series deep groove bearings at the inboard and outboard locations

- Modular power frame assembly minimizes number of parts needed

- Power frame supplied in grease lubricated design with optional immersed oil lubrication