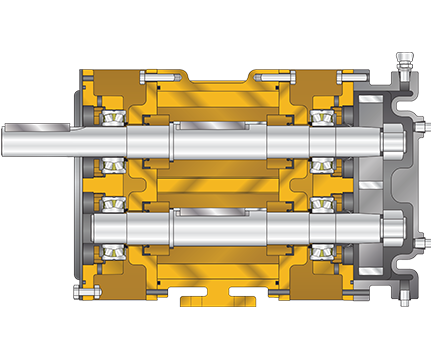

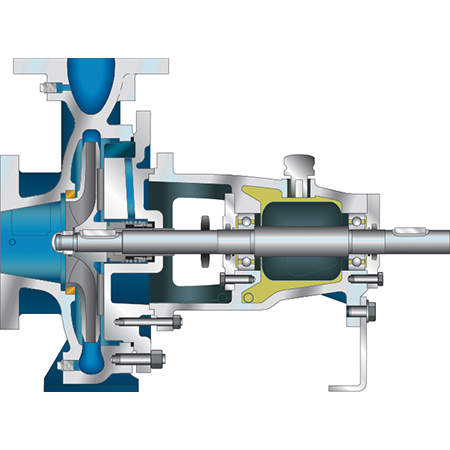

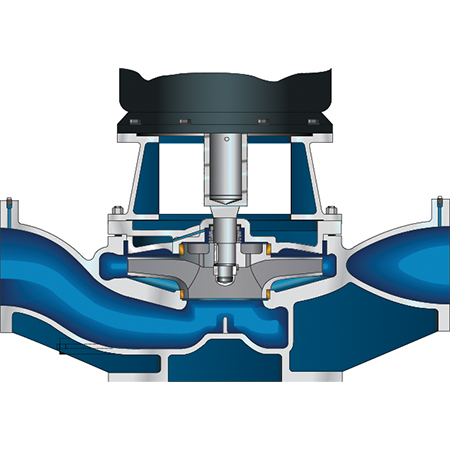

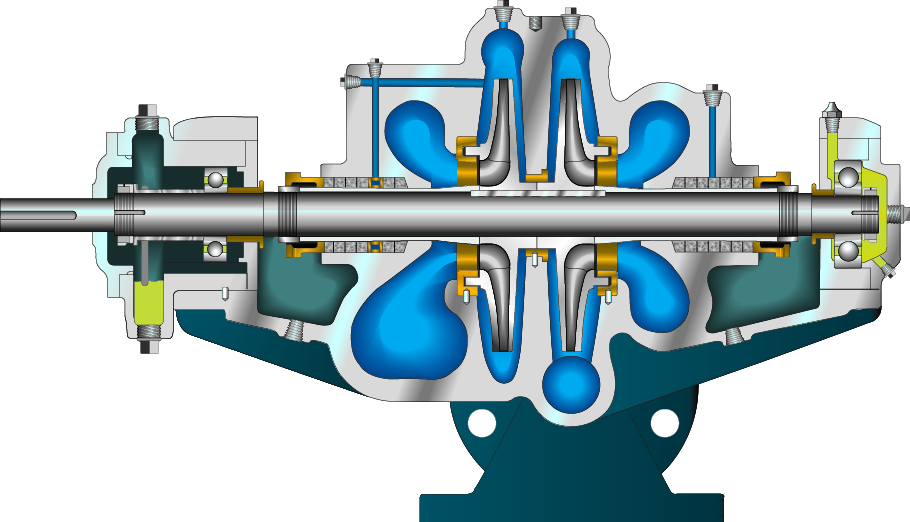

Internal flush plan to lubricate packing or mechanical seal

420 stainless steel shaft with 304 stainless steel shaft sleeves and shaft sleeve lock nuts

Packing with lantern ring supplied standard

Combination bearing spacer with water deflector

Optional component or cartridge mechanical seals

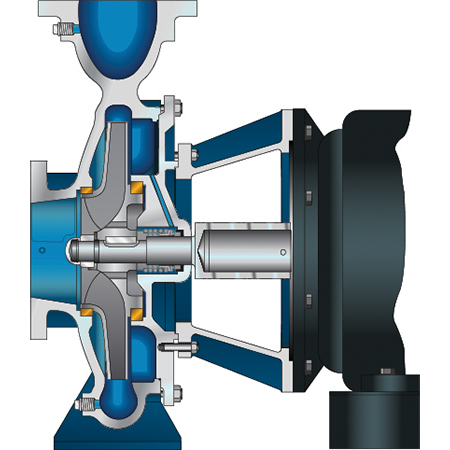

Investment cast, 304 stainless steel, impellers

Purge grease lubrication standard

Heavy wall A48 class 30 cast iron casing assembly

Optional ring oil bearing lubrication

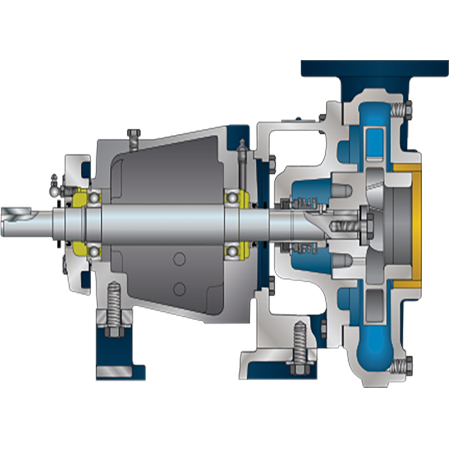

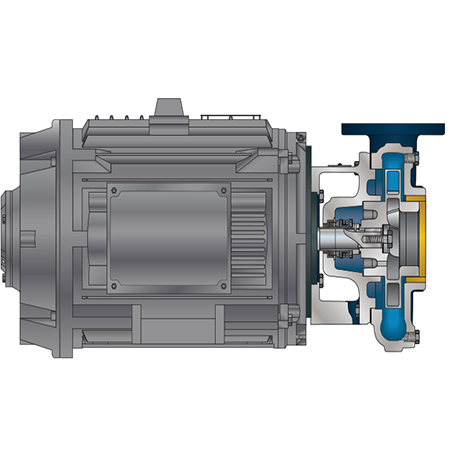

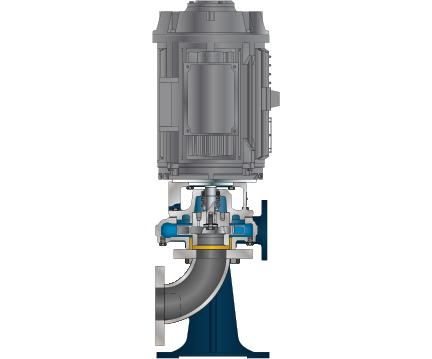

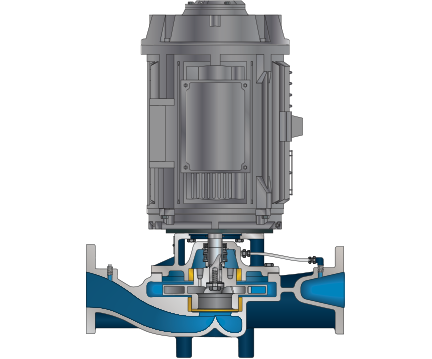

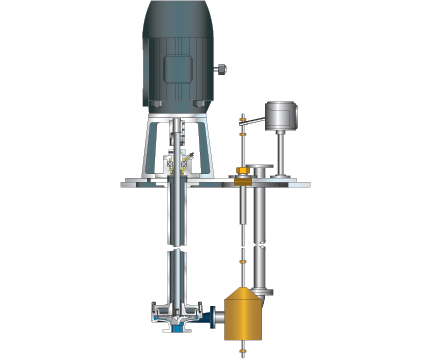

Series 3620 HL(2)

Two Stage Split Case Pumps

FEATURES & BENEFITS

The Series 3620 HL(2) Two Stage Split Case product line is a complete split case offering with a very diverse flow and pressure envelop. This product is used in a variety of industrial and commercial boiler feed.

Performance:

Flows: To 900 GPM [204 M3/HR]

Heads: To 950 FEET [290 M]

Speeds: 3550 RPM, 2950 RPM

The 3620 Series HL(2) Two Stage Split Case product line has the following specifiable features and benefits:

- ASTM A548 cast iron casing with 250 PSI pressure ratings

- 250# suction & discharge flanges (optional RF flanges)

- High efficiency impeller design that lead the industry on lower horsepower

- Investment cast, 304 stainless steel impeller

- Opposed impeller design designed to balance axial thrust

- 420 stainless steel shafting

- 304 stainless steel shaft sleeves, 304 stainless steel glands and 304 stainless steel lantern rings

- 304 stainless steel flush lines with 304 stainless steel ball valves

- Labyrinth style case wear rings to minimize pressure loss

- 6300 series deep groove bearing at the inboard and outboard locations

- Modular rotating assembly groups minimizes number of parts needed