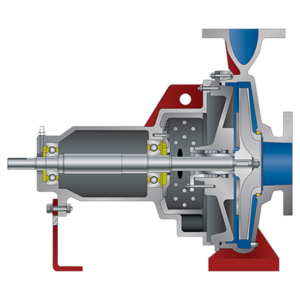

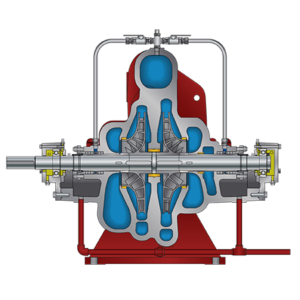

Ductile iron, centerline discharge casing with investment cast 304SS impeller & 125# suction and discharge flanges with a wade variety of optional metallurgy available upon request

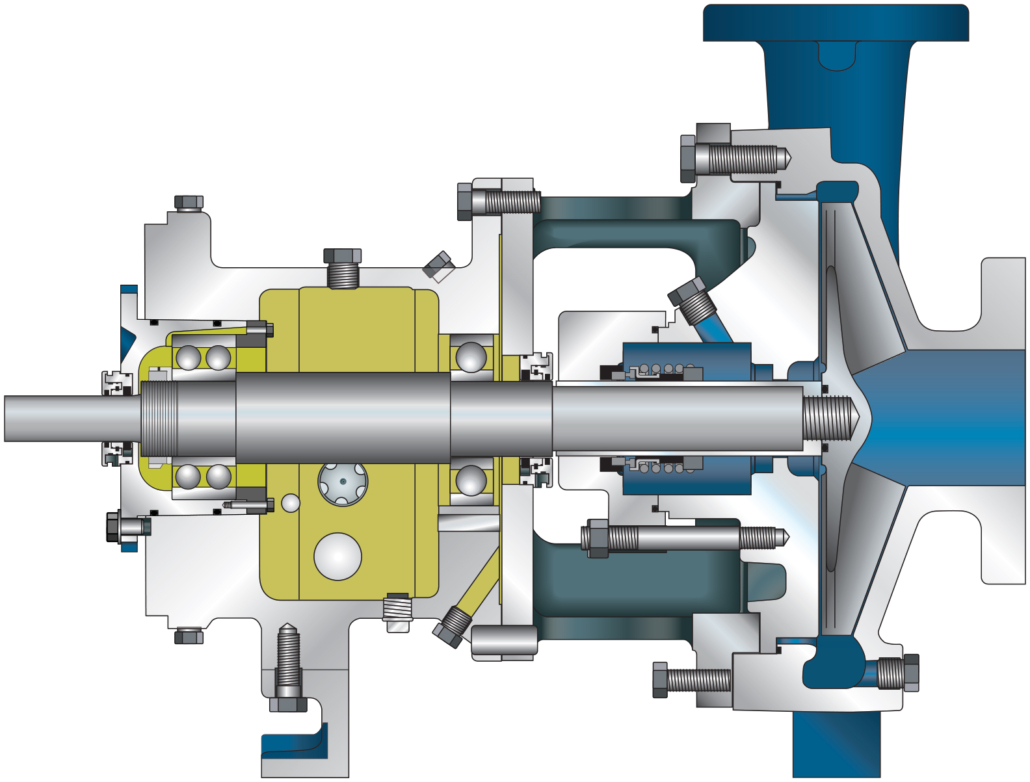

Ductile iron rear cover in small & large bore construction with external flush for component or cartridge mechanical seals

Class 30 cast iron power frame with 420SS shafting & 6200 series deep groove bearings

Mircometer adjustment to readjust semi-open impeller to factory running clearances

Back pull out modular power frame design

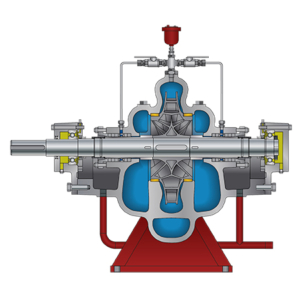

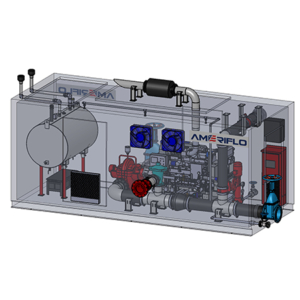

Suction and discharge locations provided with 304 stainless buffer tubing and 304 stainless steel ball valves

Semi-open, investment cast, 304 stainless steel impellers with a wade variety of optional metallurgy available upon request

Carbon/Silicone-Carbide component or cartridge mechanical seal with 300 stainless steel hardware

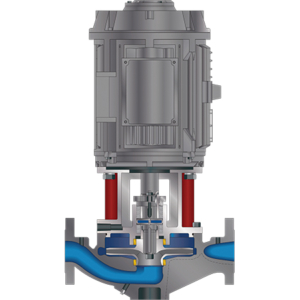

Series 4610 AEG

Flex-Coupled ANSI End Suction Pumps

FEATURES & BENEFITS

The Series 4610 AEG ANSI End Suction product line is a flex-coupled orientation with a high efficiency, centerline discharge. This product is designed for the process industry and is available in a with a wade variety of optional metallurgy available upon request.

Performance:

Flows: To 7,000 GPM [1,590 M3/HR]

Heads: To 730 Feet [223 Meters]

Sizes: 1.×1-6 To 8×10-15

Speeds: 3550 RPM, 2950 RPM, 1760 RPM, 1450 RPM, 1180 RPM, 980 RPM

The 4610 Series AEG ANSI End Suction product line has the following specifiable features and benefits:

- Ductile iron casing and rear cover with 125 PSI pressure ratings with a wade variety of optional metallurgy available upon request

- Full back pull out capability for easy maintenance

- Centerline, high efficiency, self-venting discharge casing

- 125# suction & 125# discharge flanges

- Semi-open, investment cast, 304 stainless steel impellers with a wade variety of optional metallurgy available upon request

- 420 stainless steel shafting

- 304 stainless steel shaft sleeve

- External flush for packing or mechanical seals

- 6200 series deep groove ball bearings with 7300 angular contact bearing at the outboard locations

- Modular power frame assembly minimizes number of parts needed

- Outboard bearing with Micrometer adjustment to adjust impeller clearances back to factory

- Power frame supplied in immersed oil lubrication with grease lubrication available upon request