Strainer supplied standard in 304 stainless steel construction

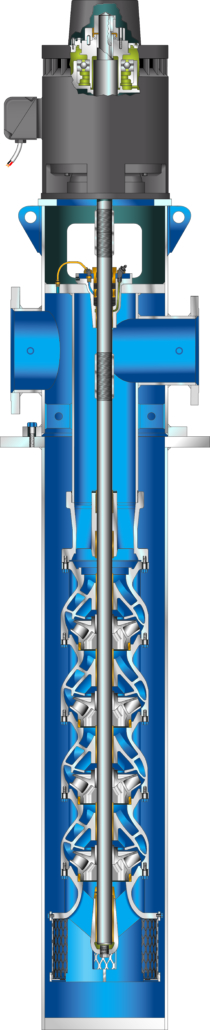

Very large hydraulic offering with high heads per stage minimizing bowl lengths

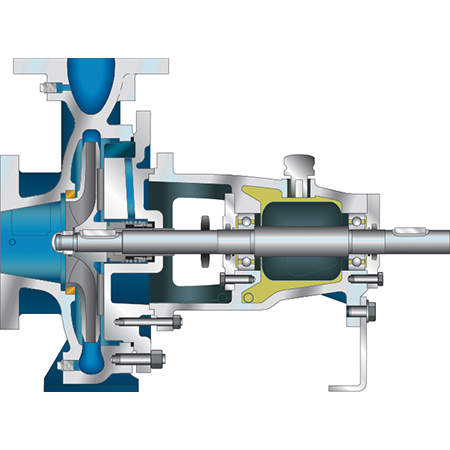

Hydraulically balanced impellers with upper and lower bowl wear rings

416 stainless steel bowl shaft supplied standard

Cast ductile iron discharge case with dual bearing support

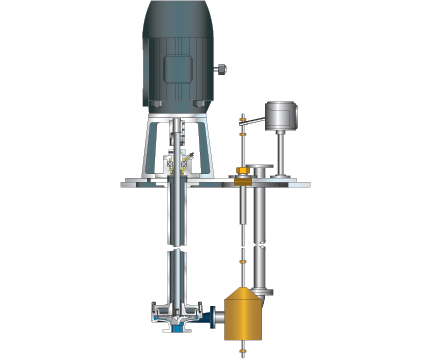

Fabricated, flanged, heavy wall column assemblies in sizes 4″ to 32″ diameter

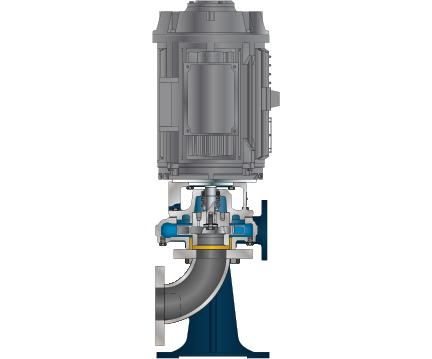

Heavy duty fabricated steel discharge heads available in “T” design or in below base suction with discharge sizes from 4″ to 36″ diameter

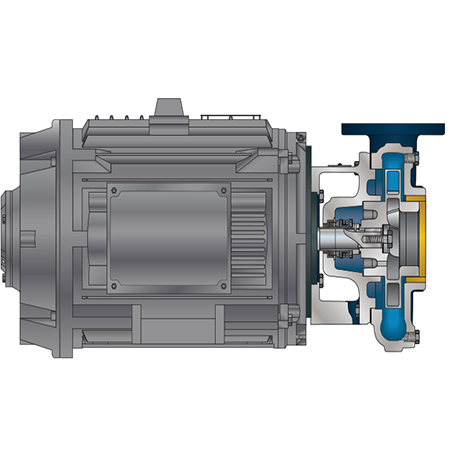

Vertical holloshaft (VHS), vertical solid, shaft (VSS) or right angle gear drive (RAG) (when Diesel engine driven) driver construction

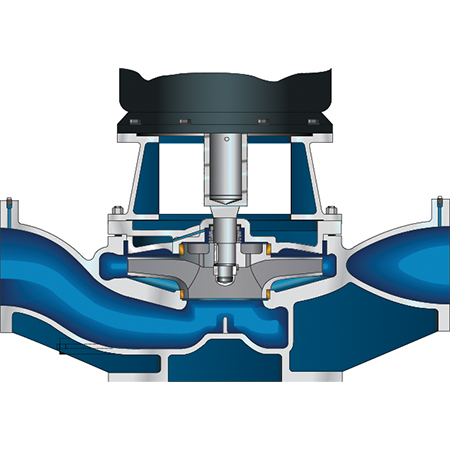

Packing or mechanical seal options available

Suction vessels available in a variety of of materials with or without suction flange

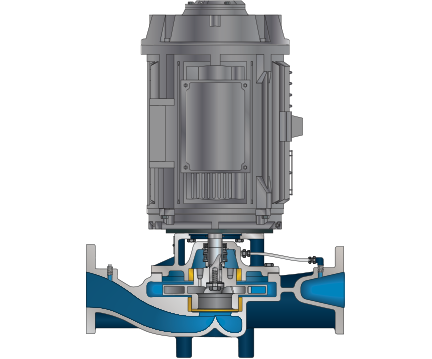

Series 4810

Open Lineshaft Fabricated Can Vertical Turbine Pumps

FEATURES & BENEFITS

The Series 4810 Can VT Vertical Turbine product line is a heavy duty vertical turbine designed for the commercial, industrial & municipal markets. These vertical turbine units have a suction vessel manufactured as part of the pumping unit and can be supplied with an fabricated inline “T” or a fabricated or cast standard discharge head with a below base suction. The Can VT Vertical Turbine can be supplied in a single or multistage orientation with a wide variety of overall length options. Pumps can be supplied in an overall length specified by the client. Optional material, packing or mechanical seal & thrust pot options are available upon request.

Performance:

Flows: To 28,000 GPM [6,359 M3/HR]

Heads: To 980 FEET [300 M]

Speeds: 3550 RPM, 2950 RPM, 1760 RPM, 1480 RPM, 1180 RPM, 980 RPM, 740 RPM, 725 RPM, 590 RPM, 490 RPM, 380 RPM

Sizes: 5AMC -> 42AMC Bowls

The 4810 Series VT Vertical Turbine product line has the following specifiable features and benefits:

- Above or below base suction flange options

- Optional basket strainers in a variety of optional metallurgy

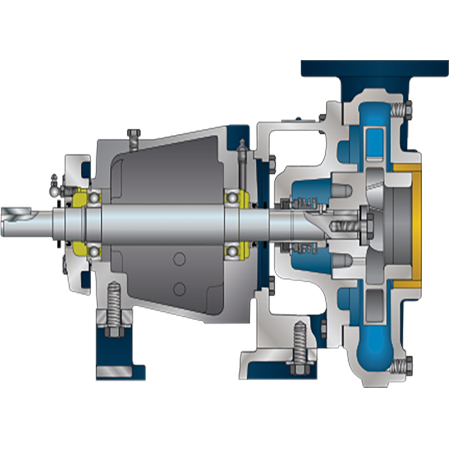

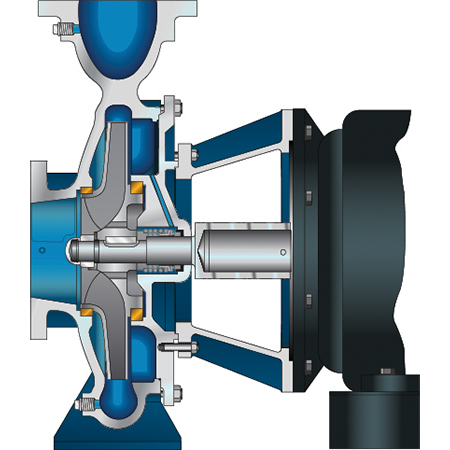

- Class 30 cast iron bowls with vitreous porcelain glass lining

- Flanged bowl construction for easy assembly and disassembly

- Investment cast, 304 stainless steel impellers

- 416 stainless steel shafting

- 304 stainless steel bolting

- Heavy duty bronze bowl bearings between each stage and under each bearing

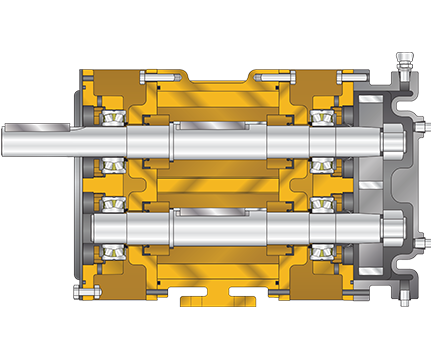

- Threaded column assemblies (4″ through 12″) with 420 stainless steel line shaft with flanged construction as an option (4″ through 48″)

- Open or enclosed lineshaft construction available

- Cast iron discharge heads (4″ through 16″)

- Optional fabricated steel discharge heads (4″ through 48″) with heavy duty double bearing stuffing box assembly

- Stuffing box features 304 stainless steel shaft sleeves, 304 stainless steel gland & 304 stainless steel lantern ring

- Options for a wide variety of component & cartridge mechanical seals

- Full optional metallurgy support for seat water applications (all bronze, all 316SS, all 2205 & 2507 super duplex stainless steel)